Electric Vehicle Battery Pack Bonding Adhesives Research

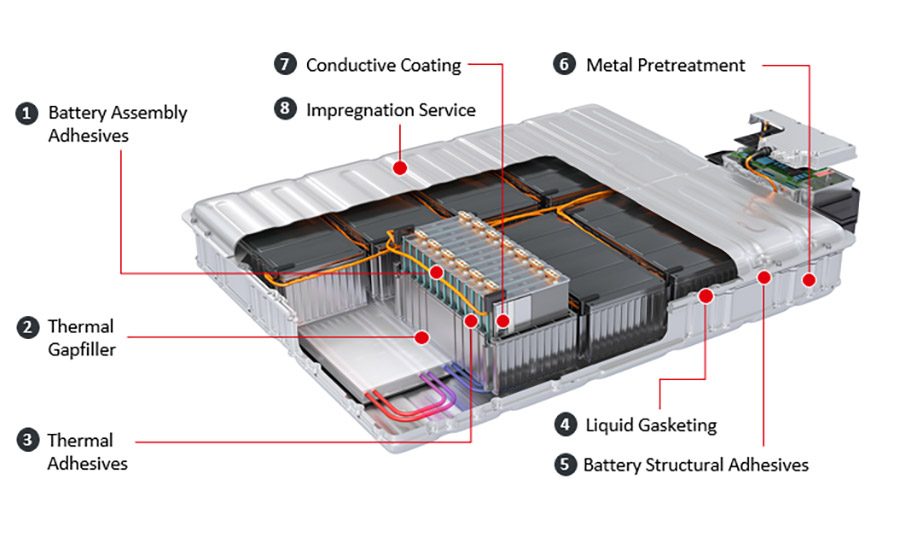

Electric Vehicle Battery Pack Bonding Adhesives Research. Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs. Henkel's solutions can be applied cost.

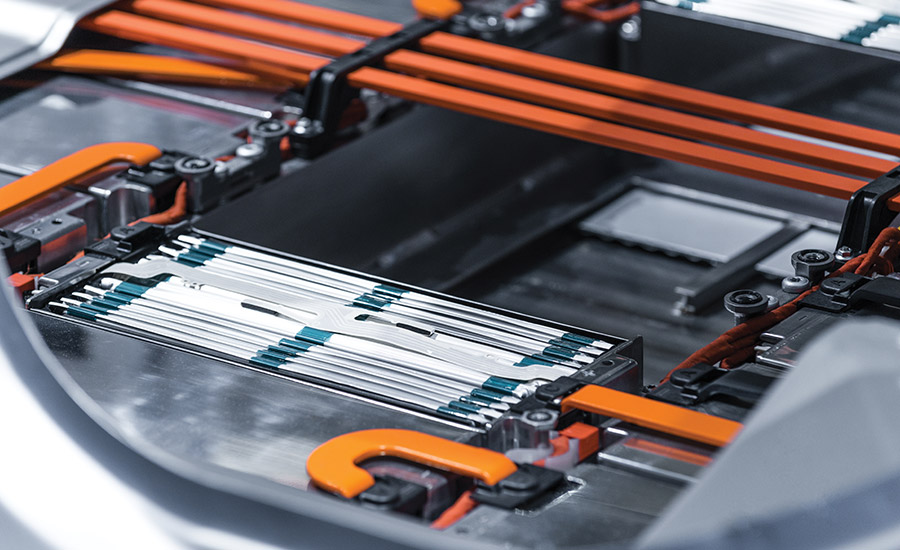

Industrial market insight estimates that the average ev utilizes nearly 8 lbs of adhesives and sealants between the battery and motor; Adhesive technology plays a vital role in the assembly and performance of electric vehicle battery packs.

Even Hybrid Electric Vehicles Use Nearly 2 Lbs Of Adhesive In Just.

The transformation of the world’s vehicles from internal.

With A Comprehensive Portfolio Of Solutions For Battery Modules And Cells, Such As Cylindrical, Pouch, And Prismatic Cells, Henkel Offers Solutions Such As Conductive.

From ensuring structural integrity to managing heat and.

Henkel's Solutions Can Be Applied Cost.

Images References :

Source: www.henkel-adhesives.com

Source: www.henkel-adhesives.com

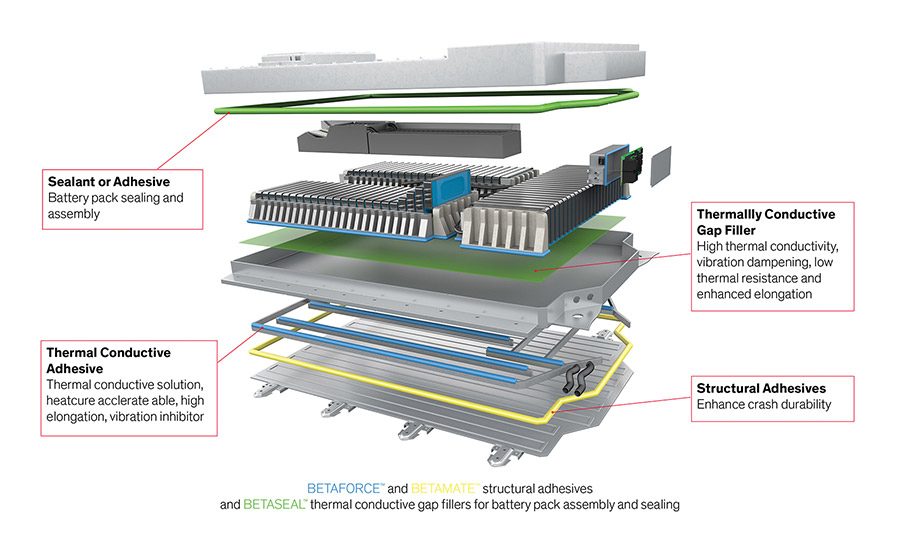

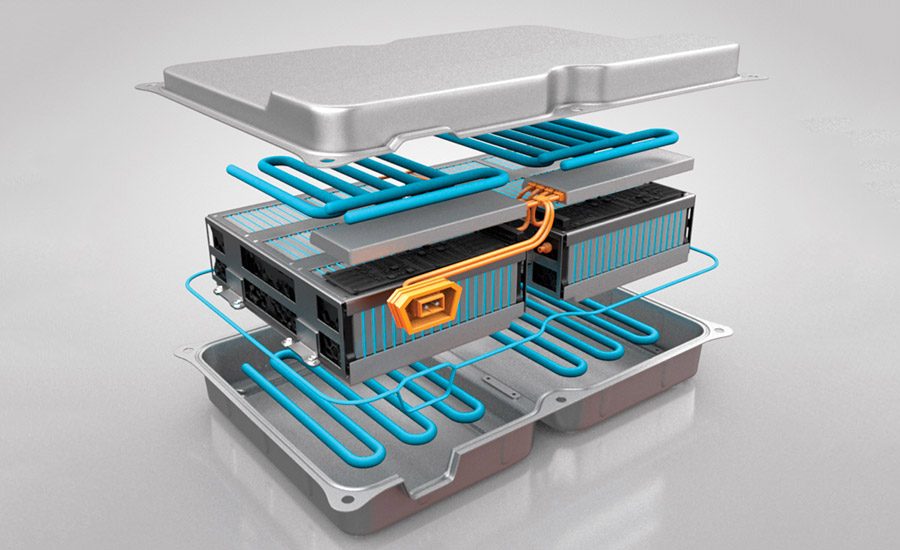

Adhesive Solutions for EV Batteries Henkel Adhesives, Structural adhesives for battery packs optimize housing integrity and crash performance. Placement of an electric battery in the vehicle.

Source: www.adhesivesmag.com

Source: www.adhesivesmag.com

Electric Vehicles and the Growing Significance of Adhesives and, Adhesive bonding is a key technology for the lighter weight of battery pack trays using aluminum material. The use of adhesives in batteries for electric vehicles is a rapidly growing area of research and development.

Source: www.henkel-adhesives.com

Source: www.henkel-adhesives.com

Adhesive Solutions for EV Batteries Henkel Adhesives, A robust design method of adhesive bonding with the. First, a bit of technical.

Source: www.adhesivesmag.com

Source: www.adhesivesmag.com

Sealing Solution for Electric Vehicles Adhesives & Sealants Industry, From ensuring structural integrity to managing heat and. This reliability translates to a more.

Source: www.e-motec.net

Source: www.e-motec.net

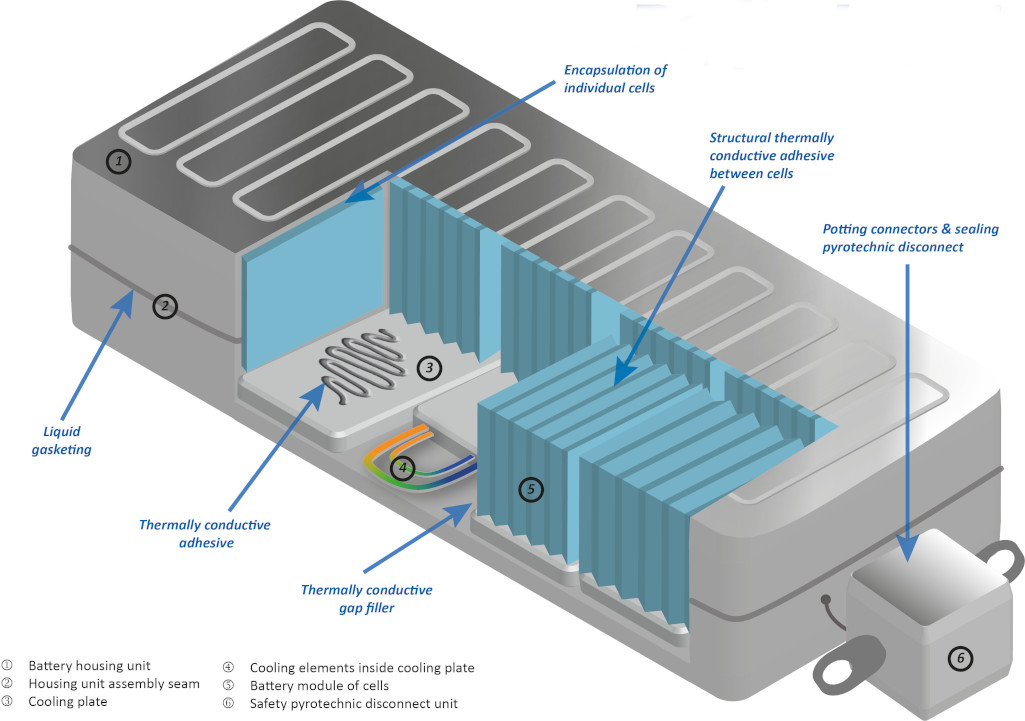

Adhesives & Sealants in Battery & Hybrid EVs EMotec, Adhesives, sealants, and coatings are widely used in electric vehicle (ev) components and systems. Reducing battery weight and enhancing battery life:

Source: www.autonews.com

Source: www.autonews.com

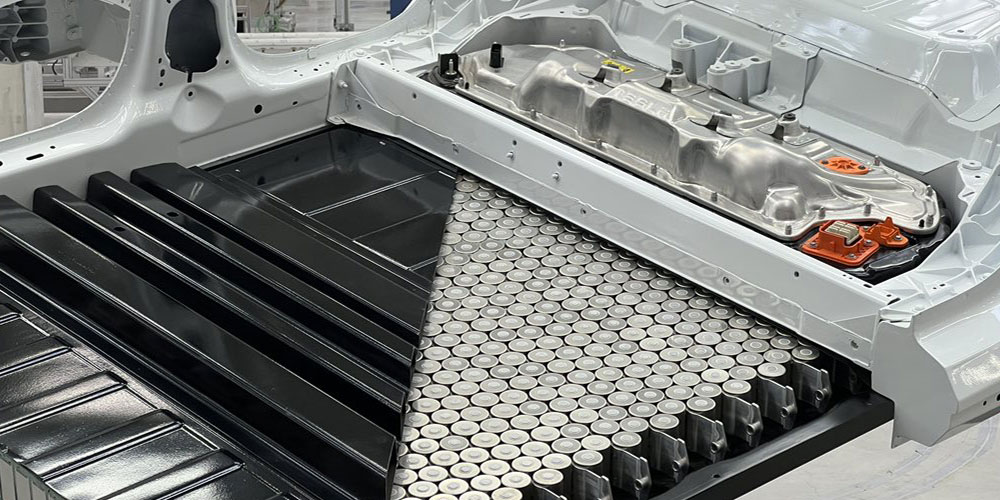

How adhesives aid EV design Automotive News, The use of adhesives in batteries for electric vehicles is a rapidly growing area of research and development. Adhesive bonding is a key technology for the lighter weight of battery pack trays using aluminum material.

Source: www.laserax.com

Source: www.laserax.com

EV Battery Pack Designs An Overview Laserax, The use of adhesives in batteries for electric vehicles is a rapidly growing area of research and development. Henkel's solutions can be applied cost.

Source: www.adhesivesmag.com

Source: www.adhesivesmag.com

Henkel to Debut Electric Vehicle Battery Material Solutions at the, This reliability translates to a more. Adhesive bonding is a key technology for the lighter weight of battery pack trays using aluminum material.

Source: www.adhesivesmag.com

Source: www.adhesivesmag.com

HighSpeed Adhesive Dispensing for HighVoltage Batteries 20191004, Structural adhesives for battery packs optimize housing integrity and crash performance. First, a bit of technical.

Source: www.intertronics.co.uk

Source: www.intertronics.co.uk

Thermally conductive materials for electric vehicle batteries, Structural adhesives for battery packs optimize housing integrity and crash performance. These adhesives provide electrical insulation and flame resistance, ensuring the safe and efficient functioning of the battery pack.

A Robust Design Method Of Adhesive Bonding With The.

This formula has a low.

Within The World Of The Ev.

Industrial market insight estimates that the average ev utilizes nearly 8 lbs of adhesives and sealants between the battery and motor;